Heat Press

The heat press is used for permanently pressing specialized heat transfer vinyl decals or dye sublimation prints onto a piece of fabric. It uses intense heat and pressure to bind the decal to the fabric. We have a Cricut EasyPress 2, which works similar to an iron with added pressure. Choose a temperature and time based on your fabric.

Before you can begin pressing your decal, you must pre-heat the heat press and set the temperature and time on the tool. Use this tool on top of the wool mat to protect work surfaces from the heat of the tool. Ideally, use this tool in the fume hood to ventilate fumes from melting plastic (as in when curing screen prints, or heat pressing vinyl). Teflon fabric should be used in between the tool and the item being heat pressed.

To create your own vinyl designs, you can use image editing software like Adobe Illustrator or Inkscape and one of the Design Center's vinyl cutters like Cricut or the Roland Desktop Cutter. You can also use the Epson SC-570 dye sublimation printer to print your design for transferring more detailed and colorful designs on synthetic fibers.

Apply the vinyl decal where you want it to appear on the fabric while taking care not to touch the iron above the press bed. Leave any backing the decal might have on. Place the protective sheet on the fabric, and close the lid locking the iron in place. Once the heat press is applied to the fabric, start the timer. The heat press will beep when the timer runs out. Remove the shirt, and allow it to cool before removing the backing from the vinyl decal.

Frequently Asked Questions

How do I know if the vinyl I have is appropriate for heat transfer?

Heat transfer vinyl has a clear backing, and that backing should be sticky. The best way to know if the vinyl is heat transfer is to peel back the vinyl a little bit and see if the backing itself is sticky.

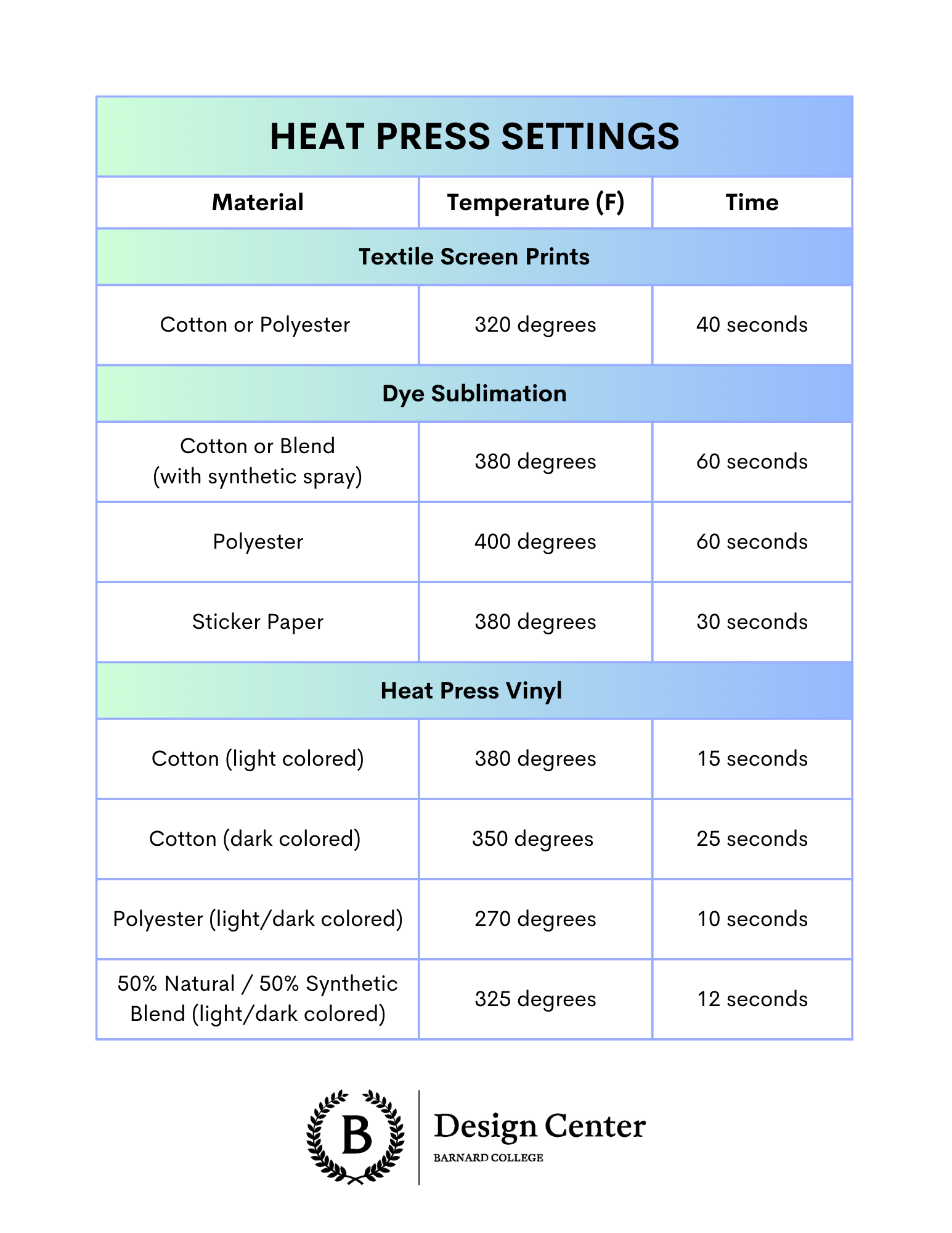

What temperature and time should I set the heat press for?

The temperature and time is dependent on the type of fabric you are pressing the decal onto. You can add additional pressure by turning the knob on top of the press.

How can I ensure I get the best possible results?

Make sure that your fabric is completely flat against the wool mat.

You can also do a short press in the beginning just enough to allow the vinyl to adhere to the fabric. Open the press, and remove the plastic backing from the vinyl. Once that is done, lower the press again, lock it in place, and wait for the countdown timer to run out.