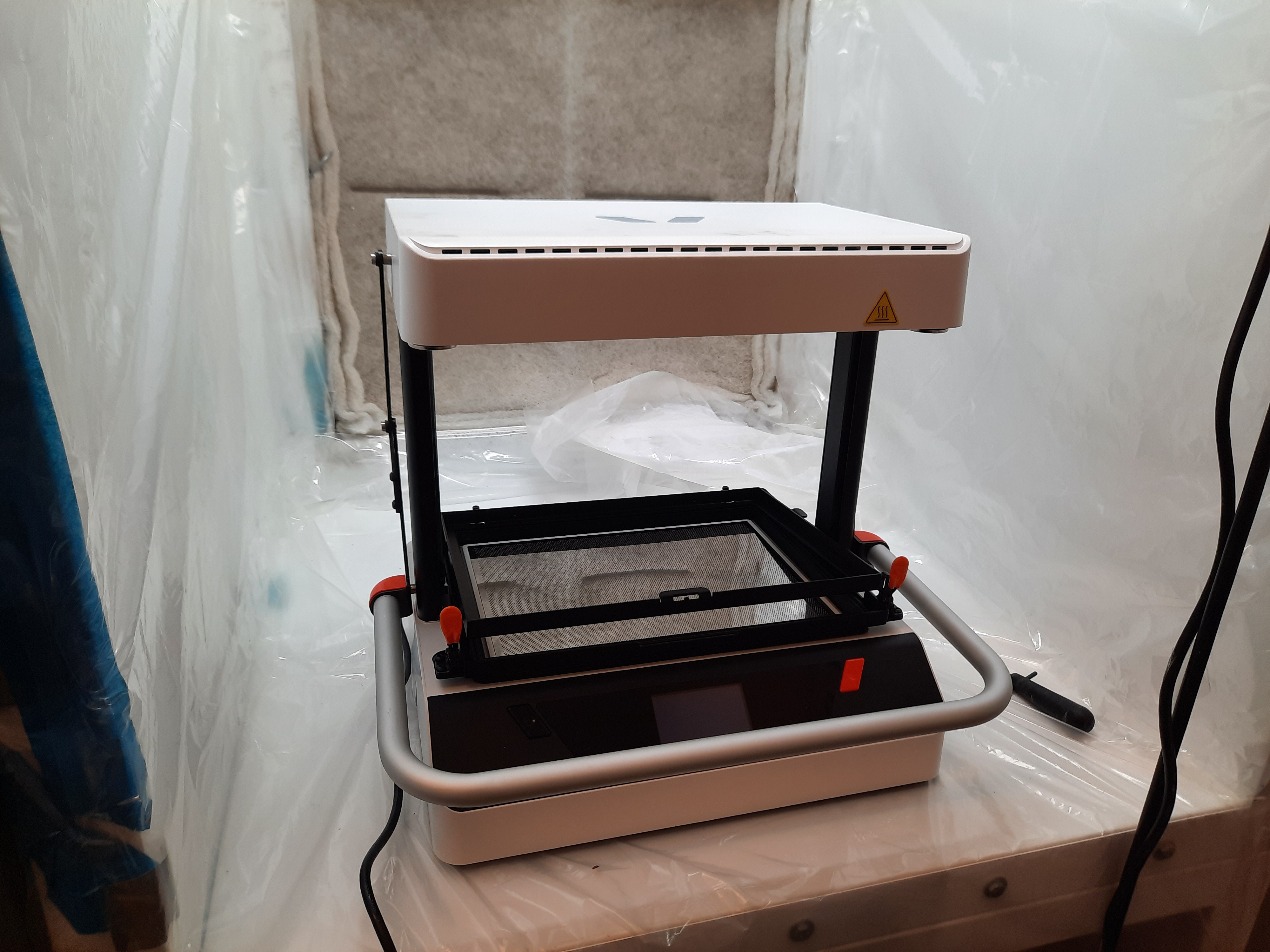

Vacuum Former

The Design Center has one Vaquform vacuum former available for use in the back room that contains the laser cutter and 3D printers. A vacuum former is a useful tool for producing objects like models and molds very quickly. In order to make a vacuum-formed shape, you must have the object you want to use the vacuum former on.

The vacuum former can generate fumes from the heated plastic sheet, so it is important to use the vacuum former inside the fume hood to provide proper ventilation. The Design Center has a number of plastic sheets that you can use in boxes next to the vacuum former.

When the machine is on, press the central button on the front panel to move through each of the settings on the display.

- First set your material type and thickness. (You can find this information on the box you got the plastic sheet from.)

- Leave the vacuum setting untouched unless you need more or less suction.

- When you pass the last setting, the orange light should go on.

- Press it to start heating up the vacuum former, which should take several minutes.

The heat source for the vacuum former is on the top, so when you're ready to start heating the plastic, raise the bar until the frame magnetically clicks into place. Put your object onto the vacuum former bed. As the plastic heats up, it will start to bend and droop down towards the bed. Once the vacuum former has reached the correct temperature, push the bar down. When the frame reaches the bed, the vacuum former will start sucking the air out from the plastic sheet causing it to be pulled flush against the surface of the object.

Tips for better results:

The vacuum former will be pulling air out through the bottom of the bed, so objects that have holes in them will pull the air through more effectively and allowing the plastic to form a tighter shape around the object. If you are using an object that you can drill holes into, consider adding some holes in any dips and pits in the object.

Larger objects can be difficult to remove from the plastic without damage its shape in the process, and it is much easier to remove an object from the mold if the object's base is its widest part. This might mean laying the object on its side or, if you're 3D printing or sculpting your object from clay, splitting the object into two halves and making a two-part mold. The plastic will be most pliable when it is hot, so it's useful to take the object quickly out of the mold. If it's cooled off significantly, you can use one of the Design Center's hand dryers to reheat the plastic to make it more flexible.